Table of Content

Some one-zone buildings have heating distributed using multiple branches or sub-loops. If you find yourself in that situation, you could convert the system into individual zone controls. To do that, simply add zone valves at each heating water pipe loops.

The most common reason a boiler gets too hot in the first place is due to limescale or sludge buildup. Do these four things when performing regular maintenance on the appliance. You’ll want to find the circulator pump; there might be more than one depending on the building. Check to see if there are heat zones since you’ve turned up the thermostat. However, it’s important to note that while it’s common for the pump to get warm, or even hot, it should never become dangerously hot.

Series Cartridge Circulators

You have to move everything out of that room, and sometimes you will have to move your whole family out of the house. Flushing the system with water will remove dirt and limescale that naturally accumulates. Without the proper water level, your boiler can be damaged beyond repair.

Things like your location, the boiler you have, and the pump’s size can affect the pricing. You’ll also need to consider whether or not you’d like to hire a professional for installation. Like you read earlier, some buildings use more than one circulator pump. Places like offices, hotels, and apartment buildings have one circulator pump for each heating zone. This can make it more difficult to pinpoint which circulator pump is causing an issue.

Boiler Circulating Pump Hot To Touch?

Here are the things you can do to keep your boiler running at tip-top shape. The easiest thing you can do is go to each pump and do the “feel test.” You can also look for excessive amounts of rust as well. A lot of rust can lead to leaks, which results in things not working properly. The average homeowner doesn’t know how exactly one of these machines works. If you’re experiencing issues with the boiler in your home and you don’t know what to do, you’re in the right place. Any dust buildup can enter your boiler and prevent it from running smoothly.

The easiest way of checking to see if the circulating pump is bad is by feeling it. If it’s on the colder side or too hot to touch, that could be a sign that there’s an issue at hand. If you’re working with a single circulator pump, it’s a lot easier to fix issues then working with multiple. You won’t have zone valves to work with, just a single pump that the controls that come with it.

Rhella E15-19 FC ΔT, P, Setpoint ECM High-Efficiency Circulator

Hard scale buildup can result in your boiler being unable to maintain normal temperatures. It also prevents the machine from working normally and efficiently. Tearing apart your drywall to insulate your walls is nothing but a hassle.

There is a hot water loop called “passive recirculation” that some seasoned plumbers suggest. This provides a return piping run to the hot-water tank, allowing natural circulation to occur. Another thing you can do is simply listen to the pump to see if it’s running. Most circulators are audible, giving off an electrical motor-like noise. If you have a Taco circulator pump, it can be hard to rely on sound because they’re so quiet.

Does Home Depot sell circulator pumps?

Apply safety methods to prevent unnecessary accidents from occurring. Hopefully, you’ll find a solution to any issues you’re facing, including a pump that’s too hot to touch. There are a few things you can do to prevent your boiler from overheating.

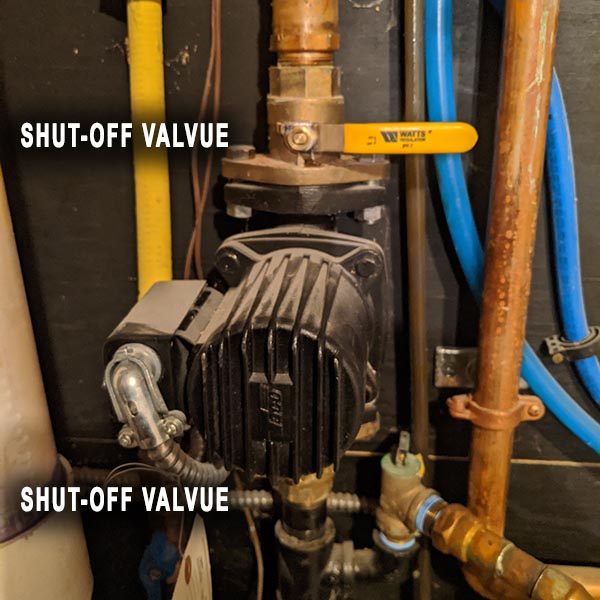

Some folks report getting a better reading on the pipes that are running OUT of the boiler more than the return side. Something to consider is how noisy the heating zone circulator pump is. If it’s gotten much louder than when initially installed, there could be a bigger issue at hand. This is usually something like a failing motor bearing, a pump impeller, or a pump assembly bearing. While it can change depending on the boiler you’re working with; circulator pumps are generally in the same place. You can find them on the return or inlet side of the heating boiler.

If it turns out you need one they are sold separately, and are cheaper than a check valve as a completely separate component. The pump of your central heating system can last a long time if it is properly installed and maintained. The pressure is too high, there are plenty of ways to avoid spending money and time fixing your boiler.

Replacing a failed circulator pump can cost as little as $400 or as much as $750 or more for the parts and labor at the time of publication. This is because the zone valve may not be opening, restricting hot water flow. The price you can pay to replace a boiler circulator pump can vary quite a bit.

When you turn the thermostat on to “heat,” you should be able to turn the heating boiler on and begin to run. Next, examine the heating system distribution piping coming out of and leading to the boiler. Then, check to see that the thermostat is set up to bring the heat by turning it up a notch.

If you plan on doing it yourself, you’ll likely just pay the price of the replacement part. If you hire a professional, you can expect to pay between $400 and $750, including parts and labor. Here are some of the average prices for boiler circulator pumps online. If there are several thermostats, you might only have one circulator.

Individual heat zones can be controlled by motorized zone valves that allow hot water flow through the loops. You can feel the circulator piping to see if everything is working properly. If you’re dealing with circulating pump issues, it could be a number of things. Just because the motor is running doesn’t mean that the pump is moving hot water through the system.

No comments:

Post a Comment